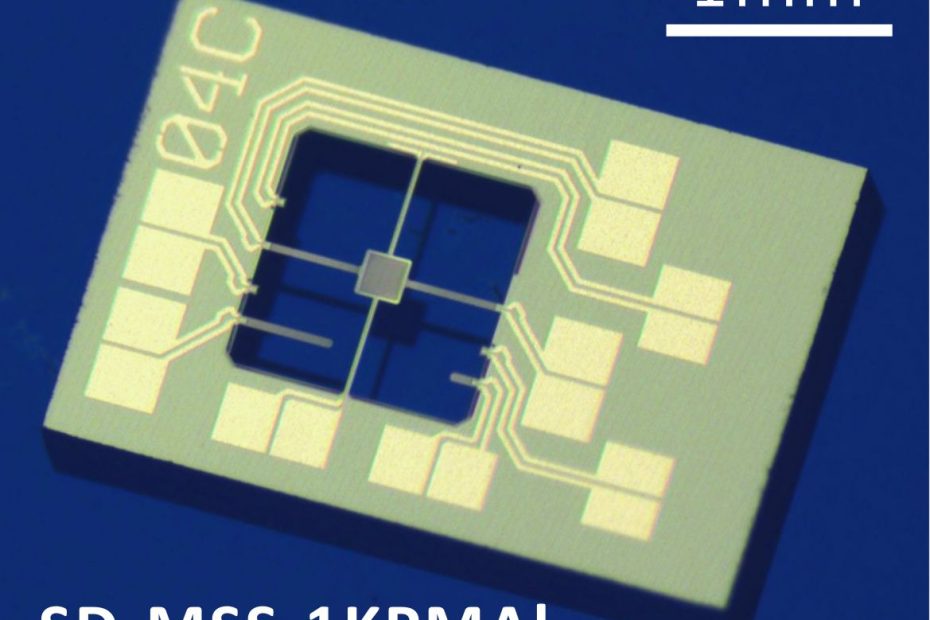

Celebrating 10 years NANOSENSORS Uniqprobe uniform quality AFM probes

10 years ago at MRS Fall 2013 NANOSENSORS introduced the first types of the Uniqprobe – uniform quality SPM probes series. During these 10 years… Read More »Celebrating 10 years NANOSENSORS Uniqprobe uniform quality AFM probes