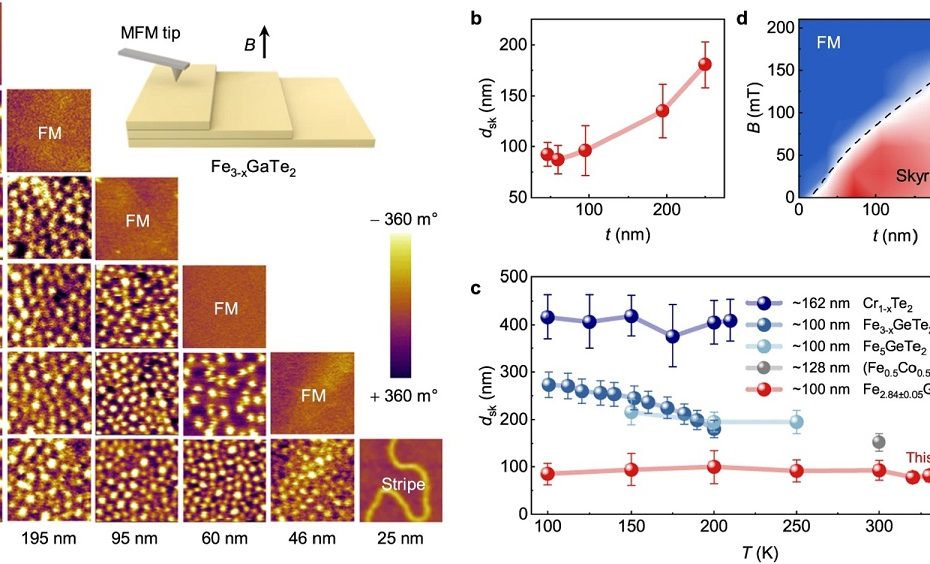

Thickness-Tunable Zoology of Magnetic Spin Txtures Observed in Fe5GeTe2

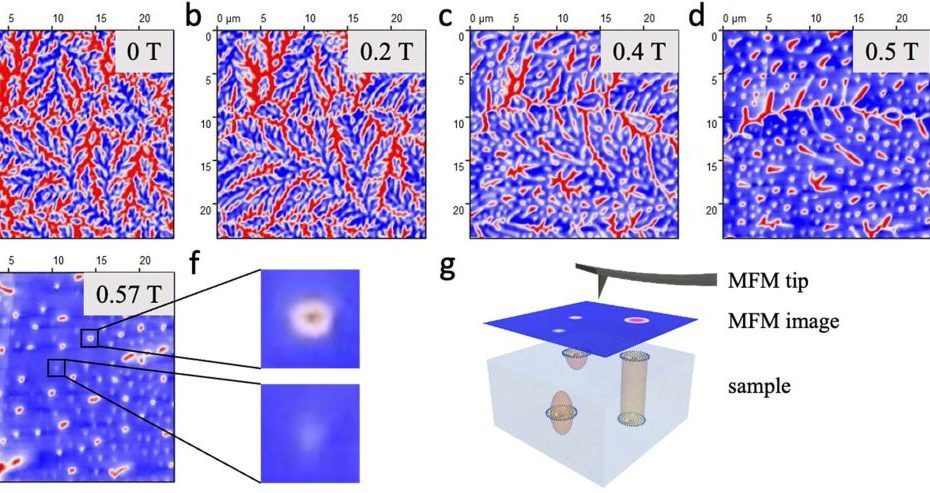

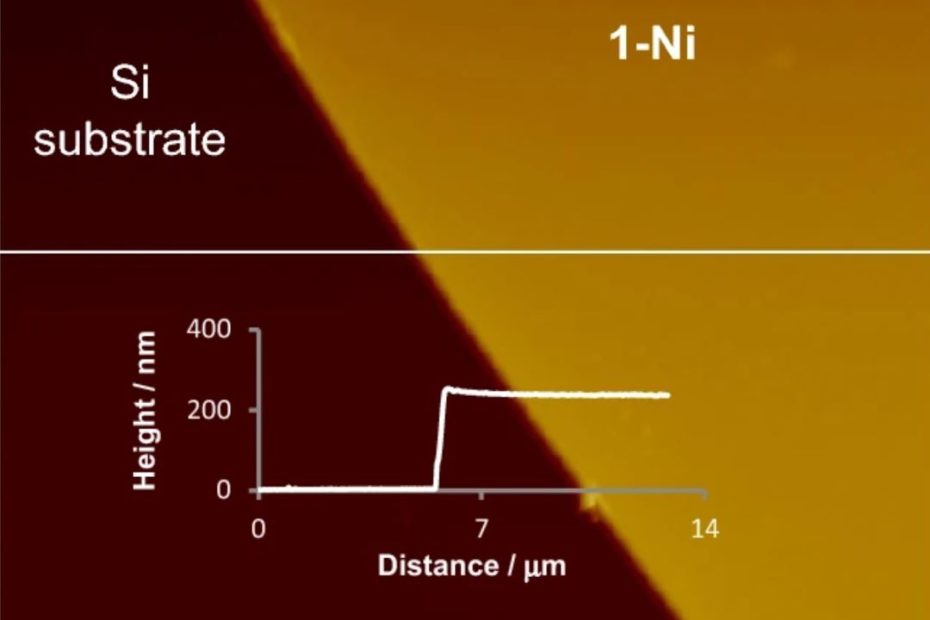

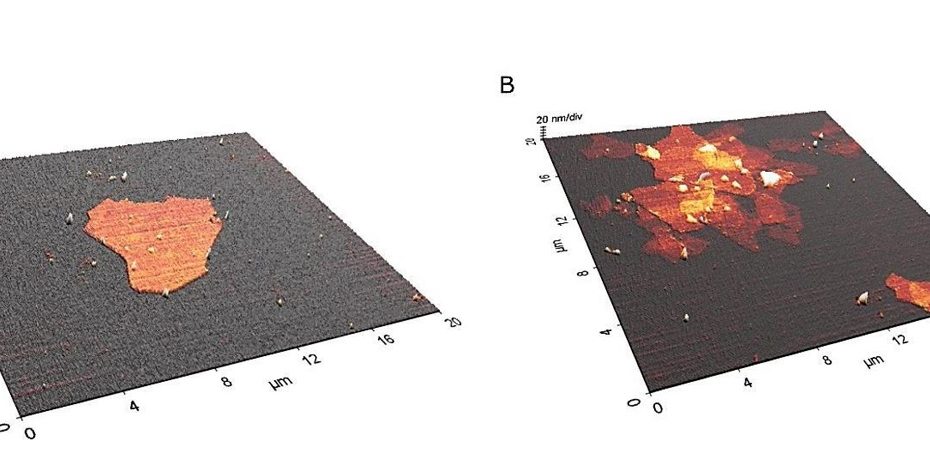

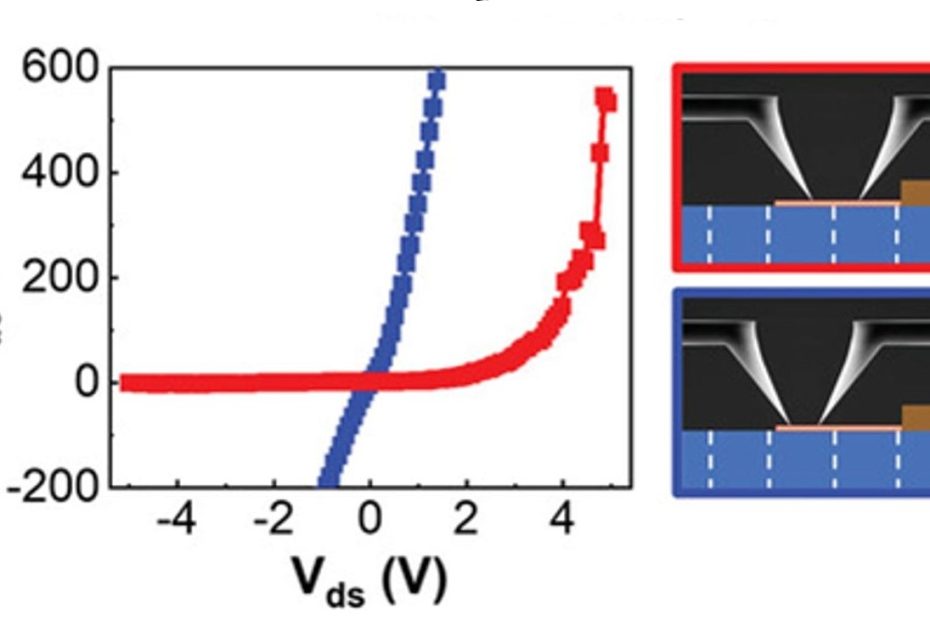

The family of two-dimensional (2D) van der Waals (vdW) materials provides a playground for tuning structural and magnetic interactions to create a wide variety of… Read More »Thickness-Tunable Zoology of Magnetic Spin Txtures Observed in Fe5GeTe2