A Bis(terpyridine)nickel(II)-Based Coordination Nanosheet: A Redox-Active Materials with Flexibility and Transparency

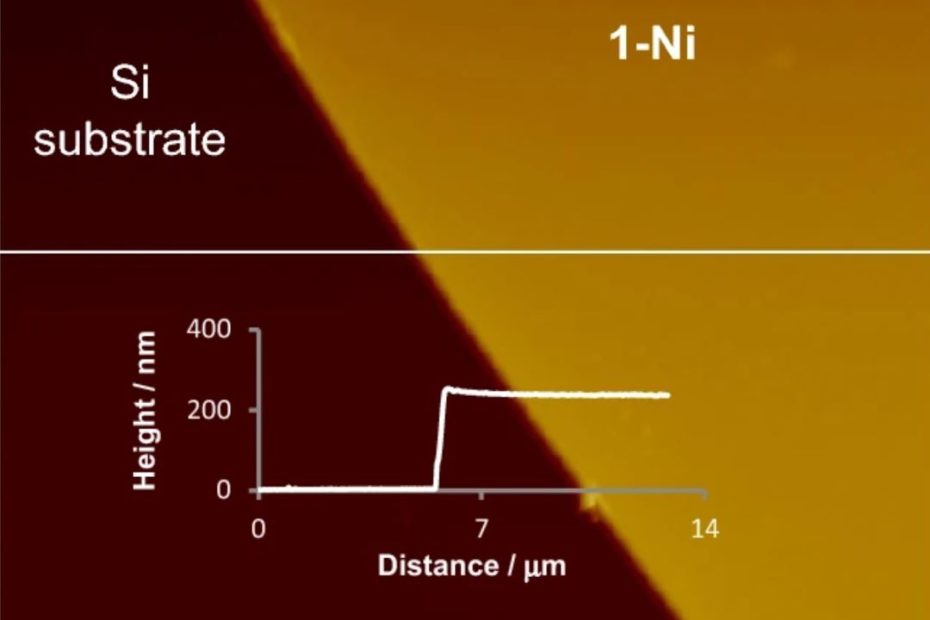

Since the discovery of graphene, extensive studies have revealed various types of novel two-dimensional polymers such as transition metal dichalcogenides, covalent organic frameworks, and carbon… Read More »A Bis(terpyridine)nickel(II)-Based Coordination Nanosheet: A Redox-Active Materials with Flexibility and Transparency