A comparative nanotribological investigation on amorphous and polycrystalline forms of MoS2

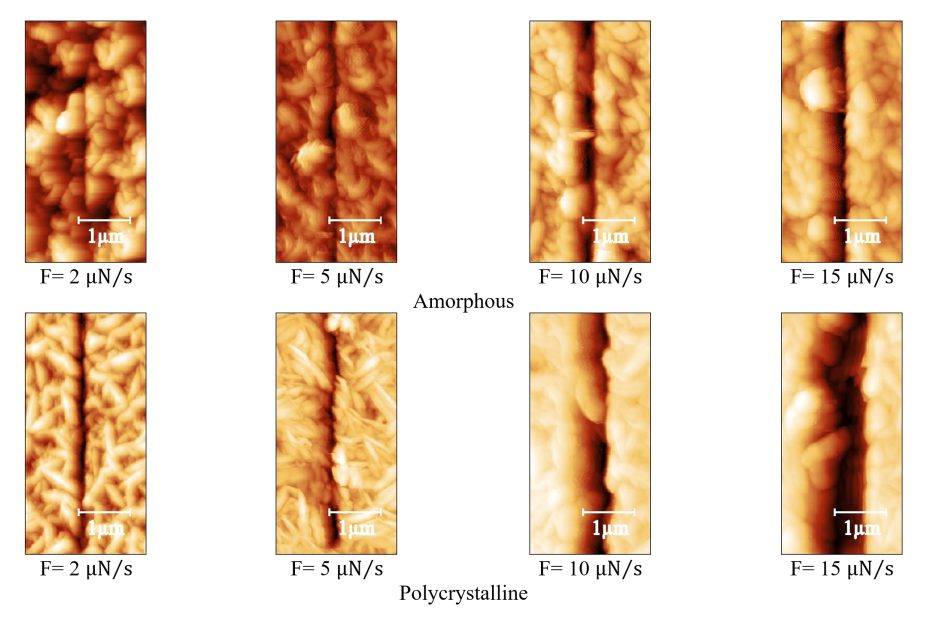

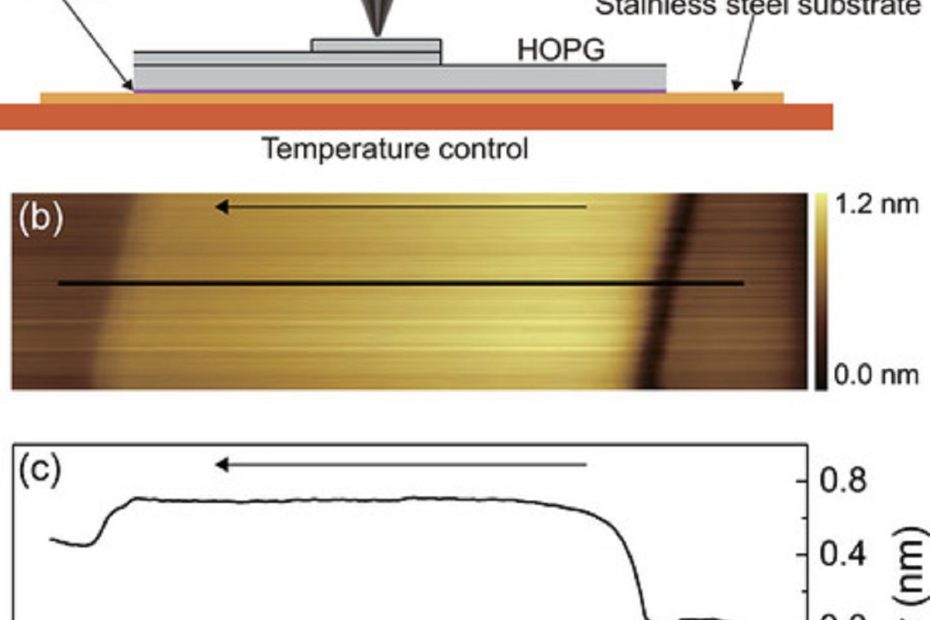

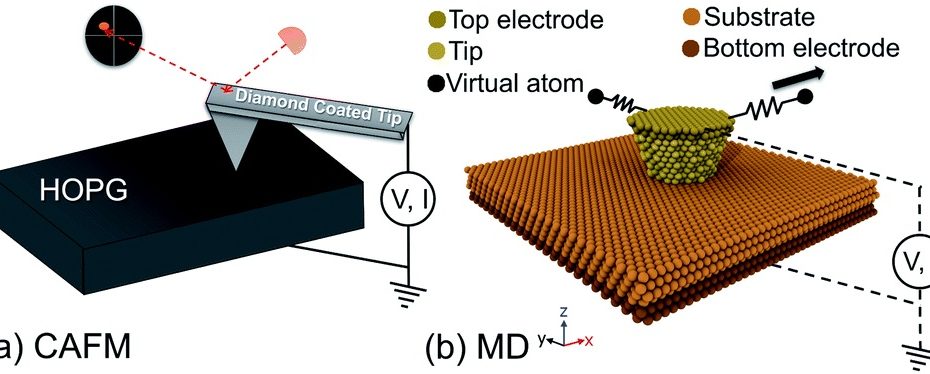

Molybdenum disulfide (MoS2) is commonly used as a dry lubricant due to its enhanced performance in the absence of oxygen and its elevated temperature stability,… Read More »A comparative nanotribological investigation on amorphous and polycrystalline forms of MoS2