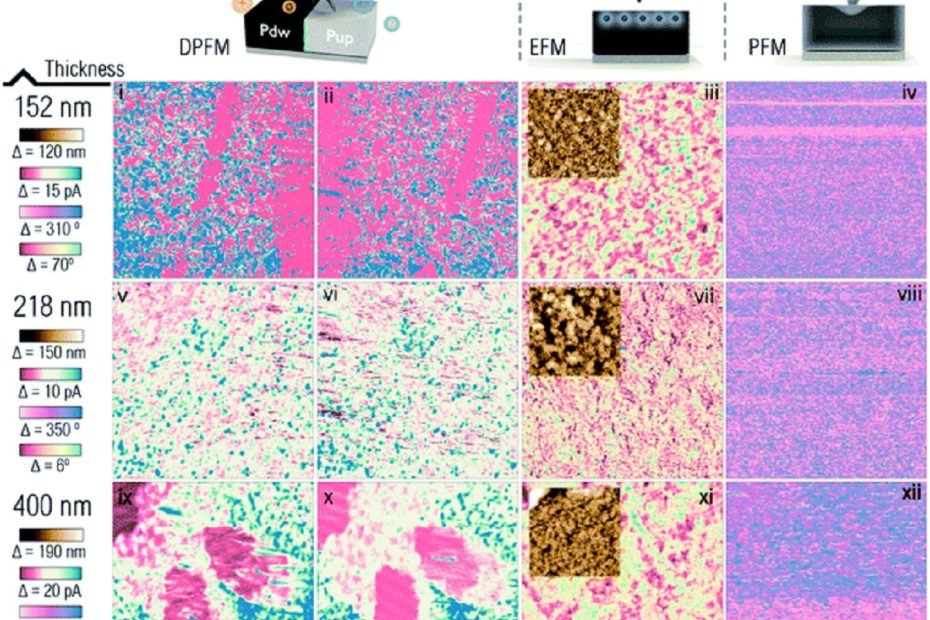

Operando Characterizations of Light-Induced Junction Evolution in Perovskite Solar Cells

Light-induced performance changes in metal halide perovskite solar cells (PSCs) have been studied intensively over the last decade, but little is known about the variation… Read More »Operando Characterizations of Light-Induced Junction Evolution in Perovskite Solar Cells