Okumura B, Yamaguchi E, Komura N, Ohtomi T, Kawano SI, Sato H, Katagiri H, Ando H, Ikeda M

Photodegradable glyco-microfibers fabricated by the self-assembly of cellobiose derivatives bearing nitrobenzyl groups

Communications Materials. 2024 Sep 10;5(1):182

DOI: https://doi.org/10.1038/s43246-024-00622-0

Vivanco-Chávez P, Klichowicz M, Popov O, Lieberwirth H, Heide G, Mertens F

Atomic Force Microscopy as a Means to Analyze Vickers Indentation Experiments: Crack Morphology, Fracture Toughness, and Indentation Profile

Minerals (2075-163X). 2024 Dec 1;14(12)

DOI: https://doi.org/10.3390/min14121193

Shintani Y, Katagiri H, Ikeda M

Oxidation‐responsive supramolecular hydrogel based on a simple fmoc‐cysteine derivative capable of showing autonomous gel–sol–gel transitions

Advanced Functional Materials. 2024 Jun;34(25):2312999

DOI: https://doi.org/10.1002/adfm.202312999

Liu H, Vampa G, Zhang JL, Shi Y, Buddhiraju S, Fan S, Vuckovic J, Bucksbaum PH, Reis DA

Beating absorption in solid-state high harmonics

Communications Physics. 2020 Oct 30;3(1):192

DOI: https://doi.org/10.1038/s42005-020-00472-5

Rognin E, Landis S, Davoust L

Viscoelastic leveling of annealed thin polystyrene films

Langmuir. 2014 Jun 17;30(23):6963-9

DOI: https://doi.org/10.1021/la5009279

Lorenzoni M, Giugni A, Torre B

Oxidative and carbonaceous patterning of Si surface in an organic media by scanning probe lithography

Nanoscale research letters. 2013 Feb 13;8(1):75

DOI: https://doi.org/10.1186/1556-276X-8-75

Torre B, Basso M, Tiribilli B, Paoletti P, Vassalli M

Disclosing and overcoming the trade-off between noise and scanning speed in atomic force microscopy

Nanotechnology. 2013 Jul 18;24(32):325104

DOI: https://doi.org/10.1088/0957-4484/24/32/325104

Juang BJ, Huang KY, Liao HS, Leong KC, Hwang S

AFM pickup head with holographic optical element (HOE)

In2010 IEEE/ASME International Conference on Advanced Intelligent Mechatronics 2010 Jul 6 (pp. 442-446). IEEE

DOI: https://doi.org/10.1109/AIM.2010.5695758

Jo A, Joo W, Jin WH, Nam H, Kim JK

Ultrahigh-density phase-change data storage without the use of heating

Nature Nanotechnology. 2009 Nov;4(11):727-31

DOI: https://doi.org/10.1038/nnano.2009.260

Hwu ET, Hung SK, Yang CW, Huang KY, Hwang S

Real-time detection of linear and angular displacements with a modified DVD opticalhead

Nanotechnology. 2008 Feb 18;19(11):115501

DOI: https://doi.org/10.1088/0957-4484/19/11/115501

Ikeda M, Ueno S, Matsumoto S, Shimizu Y, Komatsu H, Kusumoto KI, Hamachi I

Three‐Dimensional Encapsulation of Live Cells by Using a Hybrid Matrix of Nanoparticles in a Supramolecular Hydrogel

Chemistry–A European Journal. 2008 Nov 26;14(34):10808-15

DOI: https://doi.org/10.1002/chem.200801144

Kwon SJ, Jeong YM, Jeong SH

Fabrication of high-aspect-ratio silicon nanostructures using near-field scanning optical lithography and silicon anisotropic wet-etching process Applied Physics A. 2007 Jan;86(1):11-8

DOI:

https://doi.org/10.1007/s00339-006-3744-4

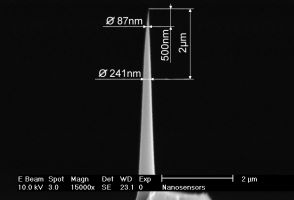

Due to their unique geometry the tips of the are more susceptible to tip damage by electrostatic discharge (ESD) than other Silicon-SPM-Probes.

Due to their unique geometry the tips of the are more susceptible to tip damage by electrostatic discharge (ESD) than other Silicon-SPM-Probes.