W. S. Chae, N. A. Mohd Yusof, K. H. Lee, S. K. Kwan, H. W. Park, J. Z. Jiang, A. Caron

Corrosion effects on the nanotribology of a Ni62Nb38 metallic glass

Applied Surface Science, Volume 573, 30 January 2022, 151628

DOI: ttps://doi.org/10.1016/j.apsusc.2021.151628

Min Cheol Kang, Hai Woong Park and Arnaud Caron

How Good Are the Performances of Graphene and Boron Nitride Against the Wear of Copper?

Materials 2021, 14(5), 1148

DOI: https://doi.org/10.3390/ma14051148

W. Yao, Q. P .Cao, S. Y. Liu, X .D. Wang, H. J .Fecht, A. Caron, D. X. Zhang, J. Z. Jiang

Tailoring nanostructured Ni-Nb metallic glassy thin films by substrate temperature

Acta Materialia, Volume 194, 1 August 2020, Pages 13-26

DOI: https://doi.org/10.1016/j.actamat.2020.04.046

Amir Abdollahi, Neus Domingo, Irene Arias and Gustau Catalan

Converse flexoelectricity yields large piezoresponse force microscopy signals in non-piezoelectric materials

Nature Communications volume 10, Article number: 1266 (2019)

DOI: https://doi.org/10.1038/s41467-019-09266-y

S. K. Kwon, H.D. Kim, X.Q. Pei, H.E. Ko, H.W. Park, R. Bennewitz and A. Caron

Effect of cooling rate on the structure and nanotribology of Ag–Cu nano-eutectic alloys

Journal of Materials Science volume 54, pages 9168–9184 (2019)

DOI: https://doi.org/10.1007/s10853-019-03533-5

H. E. Ko, H.W. Park, J.Z. Jiang, A. Caron

Nanoscopic wear behavior of face centered cubic metals

Acta Materialia, Volume 147, 1 April 2018, Pages 203-212

DOI: https://doi.org/10.1016/j.actamat.2018.01.043

H. E. Ko, S.G. Kwan, H.W. Park and A. Caron

Chemical effects on the sliding friction of Ag and Au(111)

Friction volume 6, pages 84–97 (2018)

DOI: https://doi.org/10.1007/s40544-017-0167-5

https://link.springer.com/content/pdf/10.1007/s40544-017-0167-5.pdf

S. J. Kang, K.T. Rittgen, S.G. Kwan, H.W. Park, R. Bennewitz and A. Caron

Importance of surface oxide for the tribology of a Zr-based metallic glass

Friction volume 5, pages 115–122 (2017)

DOI: https://doi.org/10.1007/s40544-017-0149-7

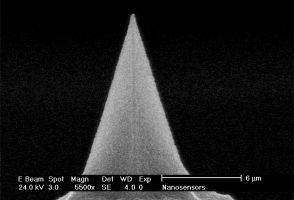

Arnaud Caron

Quantitative Hardness Measurement by Instrumented AFM-indentation

Jove, J. Vis. Exp. 2016, (117), e54706

DOI: 10.3791/54706

https://www.jove.com/t/54706/quantitative-hardness-measurement-by-instrumented-afm-indentation

Arnaud Caron and Roland Bennewitz

Lower nanometer-scale size limit for the deformation of a metallic glass by shear transformations revealed by quantitative AFM indentation

Beilstein Journal of Nanotechnology 2015, 6, 1721-1732

DOI: http://dx.doi.org/10.3762%2Fbjnano.6.176

Ayako Omura, Megumi Fukuta, Koji Miyake, Takaya Kondo, Masanori Onuma

Dominant factor of contact resistance analyzed by conductive-AFM

2014 IEEE 60th Holm Conference on Electrical Contacts (Holm), 2014, pp. 1-5

DOI: 10.1109/HOLM.2014.7031075

Maneesh Mishra, Philip Egberts, Roland Bennewitz, and Izabela Szlufarska

Friction model for single-asperity elastic-plastic contacts

Physical Review B, 2012 86, 045452

DOI: https://doi.org/10.1103/PhysRevB.86.045452

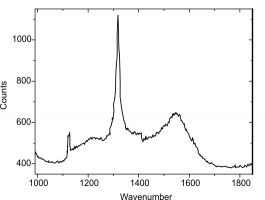

Kevin R. Moonoosawmy, Hannelore Katzke, Martha Es-Souni, Matthias Dietze, and Mohammed Es-Souni

Mesoporous and Macroporous Brookite Thin Films Having a Large Thermal Stability Range

Langmuir 2012, 28, 16, 6706–6713

DOI: https://doi.org/10.1021/la3006458